Ni izihe ngaruka za oxyde yisi idasanzwe muri ceramic?

Ubukorikori, ibikoresho byuma nibikoresho bya polymer byashyizwe kurutonde nkibikoresho bitatu bikomeye.Ceramic ifite ibintu byinshi byiza cyane, nko kurwanya ubushyuhe bwo hejuru, kurwanya ruswa, kwihanganira kwambara, nibindi, kubera ko uburyo bwo guhuza atomike ya ceramic ari ionic bond, covalent bond cyangwa imvange ya ion-covalent hamwe nimbaraga nyinshi.Ceramic ceramic irashobora guhindura isura, imiterere nimikorere yubuso bwinyuma bwa substrate, Coating-substrate composite itoneshwa kubikorwa byayo bishya.Irashobora guhuza muburyo bwambere ibiranga substrate hamwe nibiranga ubushyuhe bwo hejuru, kwihanganira kwambara cyane hamwe no kwangirika kwinshi kwibikoresho byubutaka, kandi bigatanga umukino wuzuye kubyiza byuzuye byubwoko bubiri bwibikoresho, bityo bikoreshwa cyane mukirere , indege, ingabo zigihugu, inganda zimiti nizindi nganda.

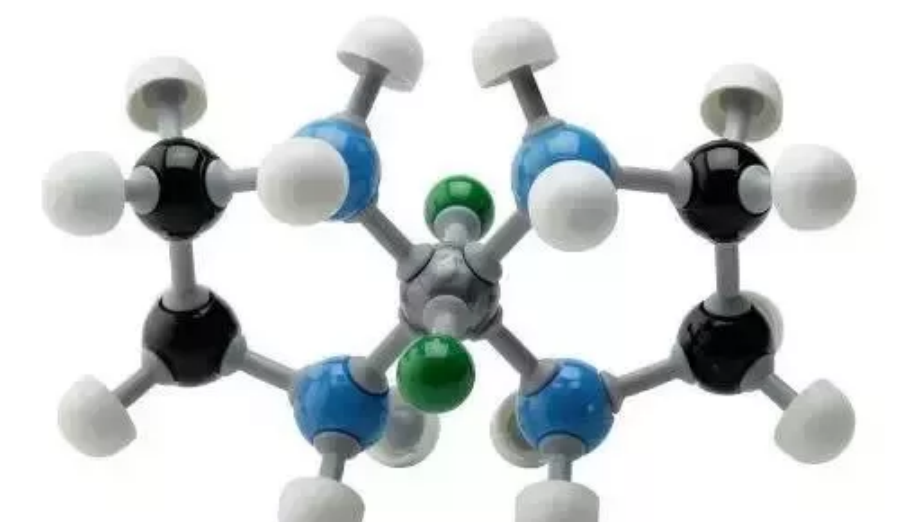

Isi idakunze kwitwa "inzu y'ubutunzi" y'ibikoresho bishya, kubera imiterere yihariye ya 4f ya elegitoroniki n'imiterere y'umubiri na shimi.Nyamara, ubutaka budasanzwe bwubutaka ntibukoreshwa gake mubushakashatsi, kandi ibinyabuzima bidasanzwe bikoreshwa cyane.Ibintu bikunze kugaragara cyane ni CeO2, La2O3, Y2O3, LaF3, CeF, CeS hamwe na ferrosilicon yubutaka budasanzwe.Iyi mibumbe idasanzwe yisi irashobora kunoza imiterere nimiterere yibikoresho byubutaka hamwe nubutaka bwa ceramic.

Ndakoresha isi idasanzwe ya oxyde mubikoresho byubutaka

Ongeraho ibintu bidasanzwe byubutaka nka stabilisateur hamwe no kwanduza sida mubutaka butandukanye birashobora kugabanya ubushyuhe bwumucyo, bikongerera imbaraga nubukomezi bwububiko bumwe na bumwe bwubatswe, bityo bikagabanya igiciro cyumusaruro.Muri icyo gihe, ibintu bidasanzwe by'isi nabyo bigira uruhare runini mu byuma byifashishwa bya gaze ya semiconductor, itangazamakuru rya microwave, ceramics piezoelectric nubundi bukorikori bukora.Ubushakashatsi bwerekanye ko, Ongeramo ibice bibiri cyangwa byinshi bidasanzwe bya okiside yubutaka kuri alumina ceramics hamwe nibyiza kuruta kongeramo oxyde imwe yisi idasanzwe mubutaka bwa alumina.Nyuma yo gukora optimizme, Y2O3 + CeO2 ifite ingaruka nziza.Iyo 0.2% Y2O3 + 0.2% CeO2 yongewe kuri 1490 ℃, ubwinshi bwikigereranyo cyurugero rwacumuye burashobora kugera kuri 96.2%, burenze ubwinshi bwintangarugero hamwe na oxyde yisi idasanzwe Y2O3 cyangwa CeO2 yonyine.

Ingaruka za La2O3 + Y2O3, Sm2O3 + La2O3 mugutezimbere gucumura ni nziza kuruta iyo kongeramo La2O3 gusa, kandi biragaragara ko kurwanya kwambara byateye imbere.Irerekana kandi ko kuvanga ibice bibiri bidasanzwe bya oxyde yisi atari inyongera yoroshye, ariko hariho imikoranire hagati yabyo, bikaba byiza cyane mugucumura no kunoza imikorere ya ceramique ya alumina, ariko ihame rikomeje kwigwa.

Byongeye kandi, usanga kongeramo ivangwa rya okiside yisi idasanzwe ivanze nka sida itera sida irashobora kunoza iyimurwa ryibikoresho, bigatera gucengera mubutaka bwa MgO no kunoza ubucucike.Nyamara, iyo ibikubiye mu cyuma kivanze cya oxyde irenze 15%, ubucucike bugereranije buragabanuka kandi poroti ifunguye iriyongera.

Icya kabiri, ingaruka za oxyde yisi idasanzwe kumiterere yububiko bwa ceramic

Ubushakashatsi buriho bwerekana ko ibintu bidasanzwe byubutaka bishobora gutunganya ingano yingano, kongera ubwinshi, kunoza microstructure no kweza isura.Ifite uruhare rudasanzwe mu kuzamura imbaraga, gukomera, gukomera, kwambara no kwangirika kwangirika kwama ceramic, biteza imbere imikorere yimyenda yubutaka ku rugero runaka kandi ikagura intera ikoreshwa ya ceramic.

1

Gutezimbere imiterere yubukanishi bwa ceramic coater na okiside yisi idasanzwe

Ntibisanzwe isi ya okiside irashobora kunoza cyane ubukana, imbaraga zunama hamwe ningufu zihuza imbaraga za ceramic.Ibisubizo byubushakashatsi byerekana ko imbaraga zingana zububiko zishobora kunozwa neza ukoresheje Lao _ 2 nkinyongera mubikoresho bya Al2O3 + 3% TiO _ 2, kandi imbaraga zingirakamaro zishobora kugera kuri 27.36MPa mugihe umubare wa Lao _ 2 ari 6.0 %.Ongeraho CeO2 hamwe nigice kinini cya 3.0% na 6.0% mubikoresho bya Cr2O3, Imbaraga zingirakamaro zo guhuza igifuniko ziri hagati ya 18 ~ 25MPa, iruta iyambere 12 ~ 16MPa Nyamara, iyo ibiri muri CeO2 ari 9.0%, uburakari imbaraga zinguzanyo zigabanuka kugeza 12 ~ 15MPa.

2

Gutezimbere ubushyuhe bwumuriro wa ceramic coating kubutaka budasanzwe

Ikizamini cyo kurwanya ubushyuhe bwa Thermal ni ikizamini cyingenzi kugirango kigaragaze neza imbaraga zihuza hagati yo gutwikisha no guhuza no guhuza ibipimo byo kwagura ubushyuhe hagati yubushyuhe na substrate.Irerekana mu buryo butaziguye ubushobozi bwo gutwikira kurwanya ibishishwa mugihe ubushyuhe bwahindutse ukundi mugihe cyo kuyikoresha, kandi ikanagaragaza ubushobozi bwo gutwikira kurwanya umunaniro ukabije wumukanishi hamwe nubushobozi bwo guhuza hamwe na substrate kuruhande. Kubwibyo, nikintu cyingenzi cyo guca urubanza ubwiza bwa ceramic.

Ubushakashatsi bwerekana ko kongeramo 3.0% CeO2 bishobora kugabanya ububobere nubunini bwa pore mu gipfukisho, kandi bikagabanya imihangayiko ihangayikishije inkombe za pore, bityo bikazamura imbaraga zo guhangana nubushyuhe bwa Cr2O3.Nyamara, ubukana bwa Al2O3 ceramic ceramic bwaragabanutse, kandi imbaraga zo guhuza hamwe nubushyuhe bwumuriro ubuzima bwa coating bwiyongereye bigaragara nyuma yo kongeramo LaO2.Iyo umubare wiyongereye wa LaO2 ari 6% (agace ka misa), Kurwanya ubushyuhe bwumuriro wa coating nibyiza, kandi ubuzima bwo gutsindwa nubushyuhe bwubuzima bushobora kugera inshuro 218, mugihe ubuzima bwo gutsindwa nubushyuhe bwumuriro utagira LaO2 ni 163 gusa ibihe.

3

Ntibisanzwe isi ya oxyde igira ingaruka kumyambarire

Ubutaka budasanzwe bukoreshwa mu kunoza imyambarire ya ceramic ni CeO2 na La2O3.Imiterere ya mpandeshatu irashobora kwerekana imikorere myiza yo gusiga no gukomeza imiti ihamye mubushyuhe bwinshi, ibyo bikaba bishobora kunoza imyambarire no kugabanya coefficient de frais.

Ubushakashatsi bwerekana ko coefficient de coiffure ya coating hamwe nubunini bukwiye bwa CeO2 ari nto kandi ihamye.Byavuzwe ko kongeramo La2O3 muri plasma yatewe nikel ishingiye kuri cermet ya cermet irashobora kugabanya kugabanuka kwambarwa hamwe na coefficient de coiffe de coiffe, kandi coefficient de friction ihagaze neza hamwe no guhindagurika guke.Ubuso bwambarwa bwububiko butagira isi idasanzwe bwerekana gufatana gukomeye no kuvunika kuvunika no gutemba, Nyamara, igifuniko kirimo isi idasanzwe cyerekana gufatana intege nke hejuru yambarwa, kandi nta kimenyetso cyerekana ahantu hanini hacitse.Microstructure yubutaka budasanzwe-butwikiriwe nubutaka burushijeho kuba bwiza kandi bworoshye, kandi imyenge iragabanuka, ibyo bigabanya imbaraga zo guteranya impuzandengo itwarwa nuduce duto twa microscopique kandi bikagabanya guterana amagambo no kwambara Doping isi idasanzwe irashobora kandi kongera intera yindege ya kirisiti ya cermets, Iyobora Kuri Guhindura Imbaraga Zimikoranire hagati yisura ebyiri za kirisiti kandi zigabanya coefficient de friction.

Incamake:

Nubwo okiside yisi idasanzwe imaze kugera kubintu byinshi mugukoresha ibikoresho bya ceramic hamwe na coatings, bishobora guteza imbere microstructure hamwe nubukanishi bwibikoresho bya ceramic na coatings, haracyari ibintu byinshi bitazwi, cyane cyane mukugabanya ubukana no kwambara.Uburyo bwo gukora Uwiteka imbaraga no kwambara birwanya ibikoresho bifatanya nuburyo bwo gusiga byahindutse icyerekezo cyingenzi gikwiye kuganirwaho mubijyanye na tribology.

Tel: + 86-21-20970332Imeri:info@shxlchem.com

Igihe cyo kohereza: Nzeri-02-2021