Why Zirconium Tetrachloride (ZrCl₄) is Critical for Modern Industries?

Zirconium Tetrachloride (ZrCl₄), the "silent hero" of advanced manufacturing, powers breakthroughs in:

- High-Performance Ceramics: Precursor for zirconia (ZrO₂) with unmatched thermal/chemical resistance

- Electronics: Essential for semiconductor CVD, optical fiber coatings, and MEMS devices

- Nuclear Energy: Key material for zirconium alloys and neutron moderation systems

- Green Catalysts: Enhances VOC abatement and petrochemical cracking efficiency

- Market Insights (Embed Interactive :

Grand View Research projects a 6.8% CAGR for ZrCl₄ demand (2023-2030), driven by electronics-grade (>99.99% purity) adoption.

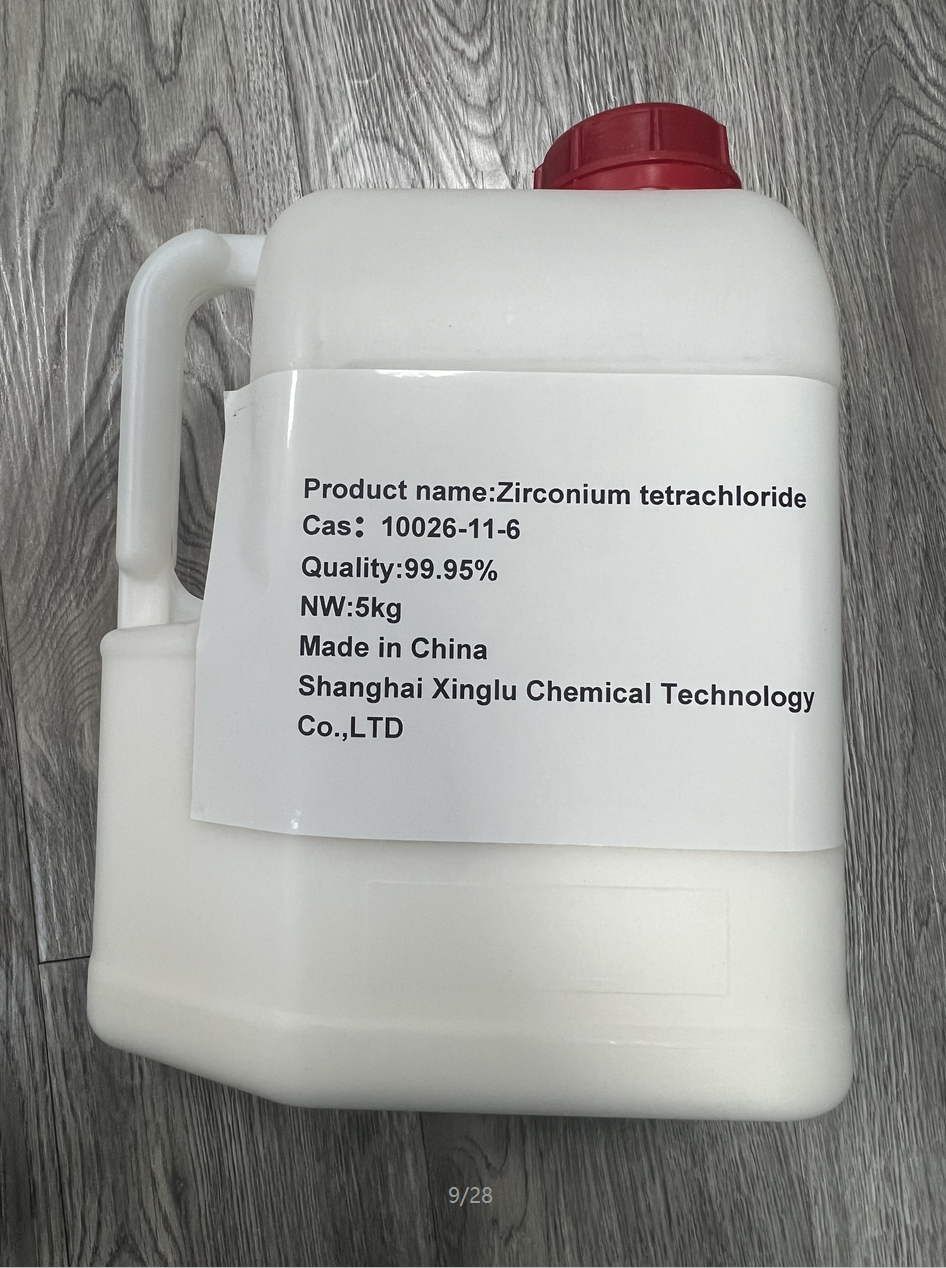

Why We Lead the Global ZrCl₄ Supply Chain?

5 Competitive Edges (With Factory Images & Process Diagrams):

- Vapor-Phase Synthesis: 99.99% purity, Cl⁻ impurities <50ppm

- Closed-Loop Production: ISO Class 7 cleanrooms, zero cross-contamination

- Real-Time QC: ICP-MS/GC analysis with full batch traceability

- Smart Packaging: Nitrogen-sealed drums, vacuum pouches, or bulk containers

- Agile Logistics: 72-hour global delivery, OEM/ODM support

Technical Specifications Comparison :

|

Parameter |

Industrial Grade (ZrCl₄-IG) |

Electronic Grade (ZrCl₄-EG) |

Industry Average |

| Purity | 99.5% | 99.99% | 98.7% |

| Chloride Impurity | ≤300ppm | ≤10ppm | 500ppm |

| Particle Size | 50-150μm | 10-50μm | Non-standardized |

| Moisture Content | ≤0.05% | ≤0.005% | 0.1% |

Top ZrCl₄ Buyer Questions

Q1: How to verify a ZrCl₄ supplier’s credibility?

- Demand: ① Live video plant tour ③ ISO 9001/14001 certificates ③ Client references (e.g., Fortune 500 partners)

Q2: Why does electronic-grade ZrCl₄ cost 3x more than industrial-grade?

- Answer: Purity refinement (+0.49%) increases production costs by 65% (see cost breakdown infographic)

Q3: What’s the safest way to handle ZrCl₄?

- Protocol: Use dry inert gas (argon/nitrogen) during transfer; store away from alkalis (show safety datasheet snippet)

Client Success Stories

Case 1: Japanese Ceramics Leader

- Challenge: Needed nano-sized zirconia precursor for 5G components

- Solution: Custom ZrCl₄ (D50=30nm, 99.995% purity)

- Result: 15% faster sintering, 98% product yield

Case 2: European Catalyst Manufacturer

- Pain Point: Chloride corrosion reduced reactor lifespan

- Innovation: Ultra-low Cl⁻ ZrCl₄ (≤5ppm) + JIT delivery

- ROI: Catalyst durability extended from 6 to 18 months

Xinglu chemical as a leading Zirconium Tetrachloride (ZrCl₄) supplier, focusing on customized services, quality assurance, and fast delivery. Get a free consultation now!

To get free samples of rare earth raw material or for more information welcome to contact us

Sales@shxlchem.com; Delia@shxlchem.com

Whatsapp& tel :008613524231522; 0086 13661632459

Post time: Apr-08-2025