The consumption of rare earths in a country can be used to determine its industrial level. Any high, precise, and advanced materials, components, and equipment cannot be separated from rare metals. Why is it that the same steel makes others more corrosion-resistant than you? Is it the same machine tool spindle that others are more durable and precise than you? Is it also a single crystal that others can reach a high temperature of 1650 ° C? Why does someone else's glass have such a high refractive index? Why can Toyota achieve the world's highest car thermal efficiency of 41%? These are all related to the application of rare metals.

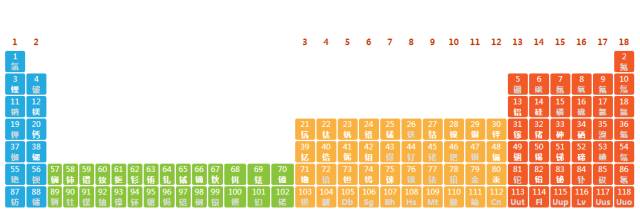

Rare earth metals, also known as rare earth elements, are a collective term for 17 elements of the scandium, yttrium, and lanthanide series in the periodic table IIIB group, commonly represented by R or RE. Scandium and yttrium are considered rare earth elements because they often coexist with lanthanide elements in mineral deposits and have similar chemical properties.

Unlike its name implies, the abundance of rare earth elements (excluding promethium) in the crust is quite high, with cerium ranking 25th in the abundance of crustal elements, accounting for 0.0068% (close to copper). However, due to its geochemical properties, rare earth elements are rarely enriched to an economically exploitable level. The name of rare earth elements is derived from their scarcity. The first rare earth mineral discovered by humans was silicon beryllium yttrium ore extracted from a mine in the village of Iterbi, Sweden, where many rare earth element names originated.

Their names and chemical symbols are Sc, Y, La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Yb, and Lu. Their atomic numbers are 21 (Sc), 39 (Y), 57 (La) to 71 (Lu).

The Discovery History of Rare Earth Elements

In 1787, Swedish C.A. Arrhenius found an unusual rare earth metal black ore in the small town of Ytterby near Stockholm. In 1794, Finnish J. Gadolin isolated a new substance from it. Three years later (1797), Swedish A.G. Ekeberg confirmed this discovery and named the new substance yttria (yttrium earth) after the place where it was discovered. Later, in memory of Gadolinite, this type of ore was called gadolinite. In 1803, German chemists M.H. Klaproth, Swedish chemists J.J. Berzelius, and W. Hisinger discovered a new substance - ceria - from an ore (cerium silicate ore). In 1839, the Swede C.G. Mosander discovered lanthanum. In 1843, Musander discovered terbium and erbium again. In 1878, Swiss Marinac discovered ytterbium. In 1879, the French discovered samarium, the Swedish discovered holmium and thulium, and the Swedish discovered scandium. In 1880, Swiss Marinac discovered gadolinium. In 1885, Austrian A. von Wels bach discovered praseodymium and neodymium. In 1886, Bouvabadrand discovered dysprosium. In 1901, the French man E.A. Demarcay discovered europium. In 1907, the French man G. Urban discovered lutetium. In 1947, Americans such as J.A. Marinsky obtained promethium from uranium fission products. It took over 150 years from the separation of yttrium earth by Gadolin in 1794 to the production of promethium in 1947.

Application of Rare Earth Elements

Rare earth elements are known as "industrial vitamins" and have irreplaceable excellent magnetic, optical, and electrical properties, playing a huge role in improving product performance, increasing product variety, and improving production efficiency. Due to its large effect and low dosage, rare earths have become an important element in improving product structure, increasing technological content, and promoting industry technological progress. They have been widely used in fields such as metallurgy, military, petrochemical, glass ceramics, agriculture, and new materials.

Metallurgical Industry

Rare earth has been applied in the metallurgical field for more than 30 years, and has formed relatively mature technologies and processes. The application of rare earth in steel and non-ferrous metals is a large and wide-ranging field with broad prospects. The addition of rare earth metals, fluorides, and silicides to steel can play a role in refining, desulfurization, neutralizing low melting point harmful impurities, and improving the processing performance of steel; Rare earth silicon iron alloy and rare earth silicon magnesium alloy are used as spheroidizing agents to produce rare earth ductile iron. Due to their special suitability for producing complex ductile iron parts with special requirements, this type of ductile iron is widely used in mechanical manufacturing industries such as automobiles, tractors, and diesel engines; Adding rare earth metals to non-ferrous alloys such as magnesium, aluminum, copper, zinc, and nickel can improve the physical and chemical properties of the alloy, as well as enhance its room temperature and high-temperature mechanical properties.

Military Field

Due to its excellent physical properties such as photoelectricity and magnetism, rare earths can form a wide variety of new materials with different properties and greatly improve the quality and performance of other products. Therefore, it is known as "industrial gold". Firstly, the addition of rare earths can significantly improve the tactical performance of steel, aluminum alloys, magnesium alloys, and titanium alloys used in the manufacturing of tanks, aircraft, and missiles. In addition, rare earths can also be used as lubricants for many high-tech applications such as electronics, lasers, nuclear industry, and superconductivity. Once rare earth technology is used in military, it will inevitably bring about a leap in military technology. In a certain sense, the overwhelming control of the US military in several local wars after the Cold War, as well as its ability to openly kill enemies with impunity, stems from its rare earth technology, such as the Superman.

Petrochemical industry

Rare earth elements can be used to make molecular sieve catalysts in the petrochemical industry, with advantages such as high activity, good selectivity, and strong resistance to heavy metal poisoning. Therefore, they have replaced aluminum silicate catalysts for petroleum catalytic cracking processes; In the production process of synthetic ammonia, a small amount of rare earth nitrate is used as a cocatalyst, and its gas processing capacity is 1.5 times larger than that of nickel aluminum catalyst; In the process of synthesizing cis-1,4-polybutadiene rubber and isoprene rubber, the product obtained using a rare earth cycloalkanoate triisobutyl aluminum catalyst has excellent performance, with advantages such as less equipment adhesive hanging, stable operation, and short post-treatment process; Composite rare earth oxides can also be used as catalysts for purifying exhaust gas from internal combustion engines, and cerium naphthenate can also be used as a paint drying agent.

Glass-ceramic

The application of rare earth elements in China's glass and ceramic industry has increased at an average rate of 25% since 1988, reaching approximately 1600 tons in 1998. Rare earth glass ceramics are not only traditional basic materials for industry and daily life, but also a major member of the high-tech field. Rare earth oxides or processed rare earth concentrates can be widely used as polishing powders for optical glass, spectacle lenses, picture tubes, oscilloscope tubes, flat glass, plastic, and metal tableware; In the process of melting glass, cerium dioxide can be used to have a strong oxidation effect on iron, reducing the iron content in the glass and achieving the goal of removing the green color from the glass; Adding rare earth oxides can produce optical glass and special glass for different purposes, including glass that can absorb ultraviolet rays, acid and heat resistant glass, X-ray resistant glass, etc; Adding rare earth elements to ceramic and porcelain glazes can reduce the fragmentation of glazes and make products present different colors and glosses, making them widely used in the ceramic industry.

Agriculture

The research results indicate that rare earth elements can increase the chlorophyll content of plants, enhance photosynthesis, promote root development, and increase nutrient absorption by roots. Rare earth elements can also promote seed germination, increase seed germination rate, and promote seedling growth. In addition to the main functions mentioned above, it also has the ability to enhance the disease resistance, cold resistance, and drought resistance of certain crops. Numerous studies have also shown that the use of appropriate concentrations of rare earth elements can promote the absorption, transformation, and utilization of nutrients by plants. Spraying rare earth elements can increase the Vc content, total sugar content, and sugar acid ratio of apple and citrus fruits, promoting fruit coloring and early ripening. And it can suppress respiratory intensity during storage and reduce decay rate.

New materials field

Rare earth neodymium iron boron permanent magnet material, with high remanence, high coercivity, and high magnetic energy product, is widely used in the electronic and aerospace industries and driving wind turbines (especially suitable for offshore power plants); Garnet type ferrite single crystals and polycrystals formed by the combination of pure rare earth oxides and ferric oxide can be used in the microwave and electronic industries; Yttrium aluminum garnet and neodymium glass made of high-purity neodymium oxide can be used as solid laser materials; Rare earth hexaborides can be used as cathode materials for electron emission; Lanthanum nickel metal is a newly developed hydrogen storage material in the 1970s; Lanthanum chromate is a high-temperature thermoelectric material; At present, countries around the world have made breakthroughs in the development of superconducting materials by using barium based oxides modified with barium yttrium copper oxygen elements, which can obtain superconductors in the liquid nitrogen temperature range. In addition, rare earths are widely used in lighting light sources through methods such as fluorescent powder, intensifying screen fluorescent powder, three primary color fluorescent powder, and copy lamp powder (but due to the high cost caused by the rise in rare earth prices, their applications in lighting are gradually decreasing), as well as electronic products such as projection televisions and tablets; In agriculture, applying trace amounts of rare earth nitrate to field crops can increase their yield by 5-10%; In the light textile industry, rare earth chlorides are also widely used in tanning fur, fur dyeing, wool dyeing, and carpet dyeing; Rare earth elements can be used in automotive catalytic converters to convert major pollutants into non-toxic compounds during engine exhaust.

Other applications

Rare earth elements are also applied to various digital products, including audiovisual, photography, and communication devices, meeting multiple requirements such as smaller, faster, lighter, longer usage time, and energy conservation. At the same time, it has also been applied to multiple fields such as green energy, healthcare, water purification, and transportation.

Post time: Aug-16-2023