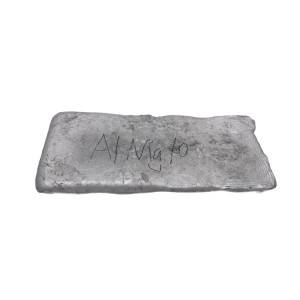

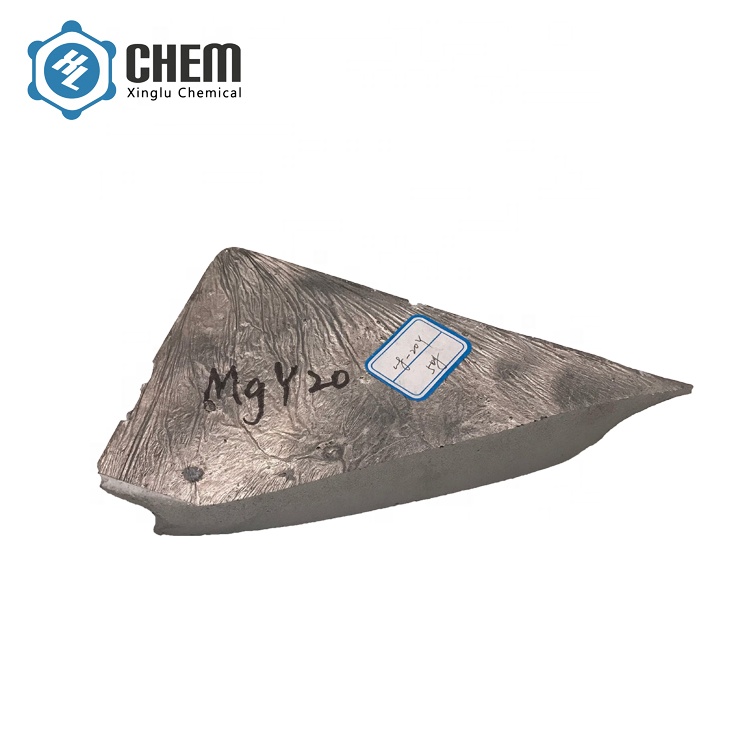

Premium Magnesium Yttrium master Alloy | Mg-Y Alloy supplier

Product Introduction

Magnesium-Yttrium (Mg-Y) alloy is a revolutionary lightweight material engineered to deliver exceptional strength, corrosion resistance, and thermal stability. Designed for industries demanding precision and durability, our Mg-Y alloy combines the benefits of magnesium’s low density with yttrium’s unique ability to enhance mechanical properties. Whether for aerospace, automotive, medical devices, or energy systems, this alloy redefines performance standards while reducing environmental impact.

Product Specifications

Our Mg-Y alloy is available in multiple grades to suit diverse industrial requirements. Below are our flagship models:

| Model | Mg Content (%) | Y Content (%) | Density (g/cm³) | Tensile Strength (MPa) | Max Temp. Resistance (°C) |

|---|---|---|---|---|---|

| MGY-100 | 92 | 8 | 1.85 | 320 | 350 |

| MGY-200 | 95 | 5 | 1.82 | 280 | 300 |

| MGY-300 | 90 | 10 | 1.88 | 360 | 400 |

Customizable parameters: Thickness (0.5–50 mm), dimensions, surface treatments (anodizing, coating), and mechanical properties.

Applications Across Industries

1️⃣ Aerospace & Defense

- Use Cases: Engine components, satellite frames, UAV parts.

- Benefits: Reduces aircraft weight by 20–30% vs. aluminum, improving fuel efficiency and payload capacity.

2️⃣ Automotive Manufacturing

- Use Cases: Transmission housings, battery casings for EVs, structural brackets.

- Benefits: Enhances EV range by lowering vehicle mass; meets crash-test standards.

3️⃣ Medical Devices

- Use Cases: Surgical tools, implantable devices, MRI machine components.

- Benefits: Biocompatible, non-magnetic, and sterilizable.

4️⃣ Electronics

- Use Cases: Laptop chassis, smartphone frames, heat sinks.

- Benefits: Superior heat dissipation and electromagnetic shielding.

5️⃣ Renewable Energy

- Use Cases: Wind turbine blades, solar panel frames.

- Benefits: Corrosion-resistant in harsh environments; extends equipment lifespan.

[Insert application collage image with alt-text: "Mg-Y alloy in aerospace, automotive, and medical industries"]

Why Choose Our Magnesium-Yttrium Alloy?

✅ Unmatched Strength-to-Weight Ratio

With a tensile strength of up to 360 MPa and density 35% lower than aluminum, Mg-Y alloy outperforms traditional metals in weight-critical applications.

✅ Superior Corrosion Resistance

Yttrium forms a stable oxide layer, providing 5x better corrosion resistance than standard magnesium alloys (tested per ASTM B117).

✅ High-Temperature Performance

Operates reliably up to 400°C, ideal for engines and energy systems.

✅ Eco-Friendly & Recyclable

100% recyclable with a 50% lower carbon footprint vs. titanium production.

✅ Tailored Solutions

Adjust composition, dimensions, and finishes to meet your exact needs.

Customization Services

We collaborate closely with clients to develop bespoke Mg-Y alloy solutions:

- Material Adjustments: Optimize Yttrium content (3–40%) for specific strength or ductility requirements.

- Precision Machining: CNC milling, casting, or 3D printing for complex geometries.

- Certifications: ISO 9001, ASTM, RoHS, and REACH compliance.

FAQs

Q: What makes Mg-Y alloy better than standard magnesium alloys?

A: Yttrium enhances grain structure, improving strength and corrosion resistance.

Q: Can Mg-Y alloy replace aluminum in automotive applications?

A: Yes! It reduces weight by 35% while maintaining comparable strength.

Q: What’s the lead time for custom orders?

A: 2–4 weeks for most projects, depending on complexity.